|

|

Iron Gall Ink TreatmentMSA SC 5458-48-6

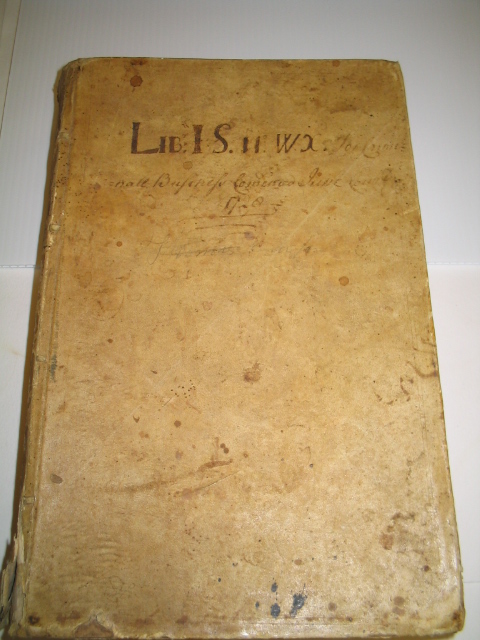

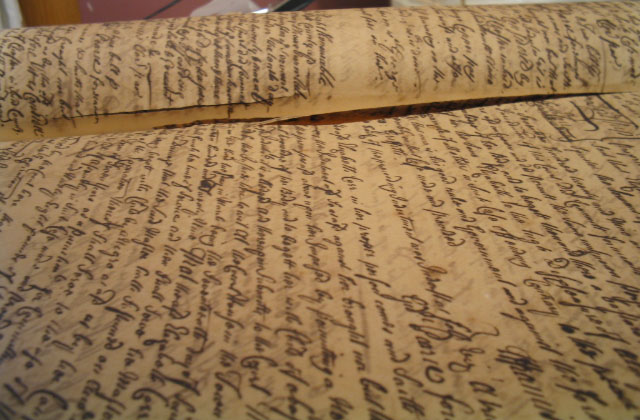

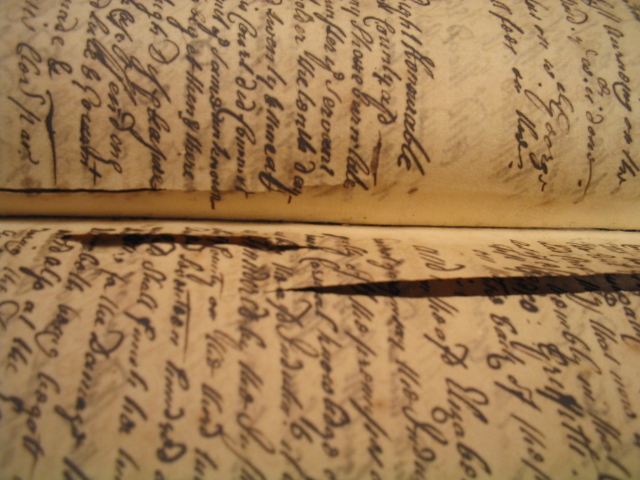

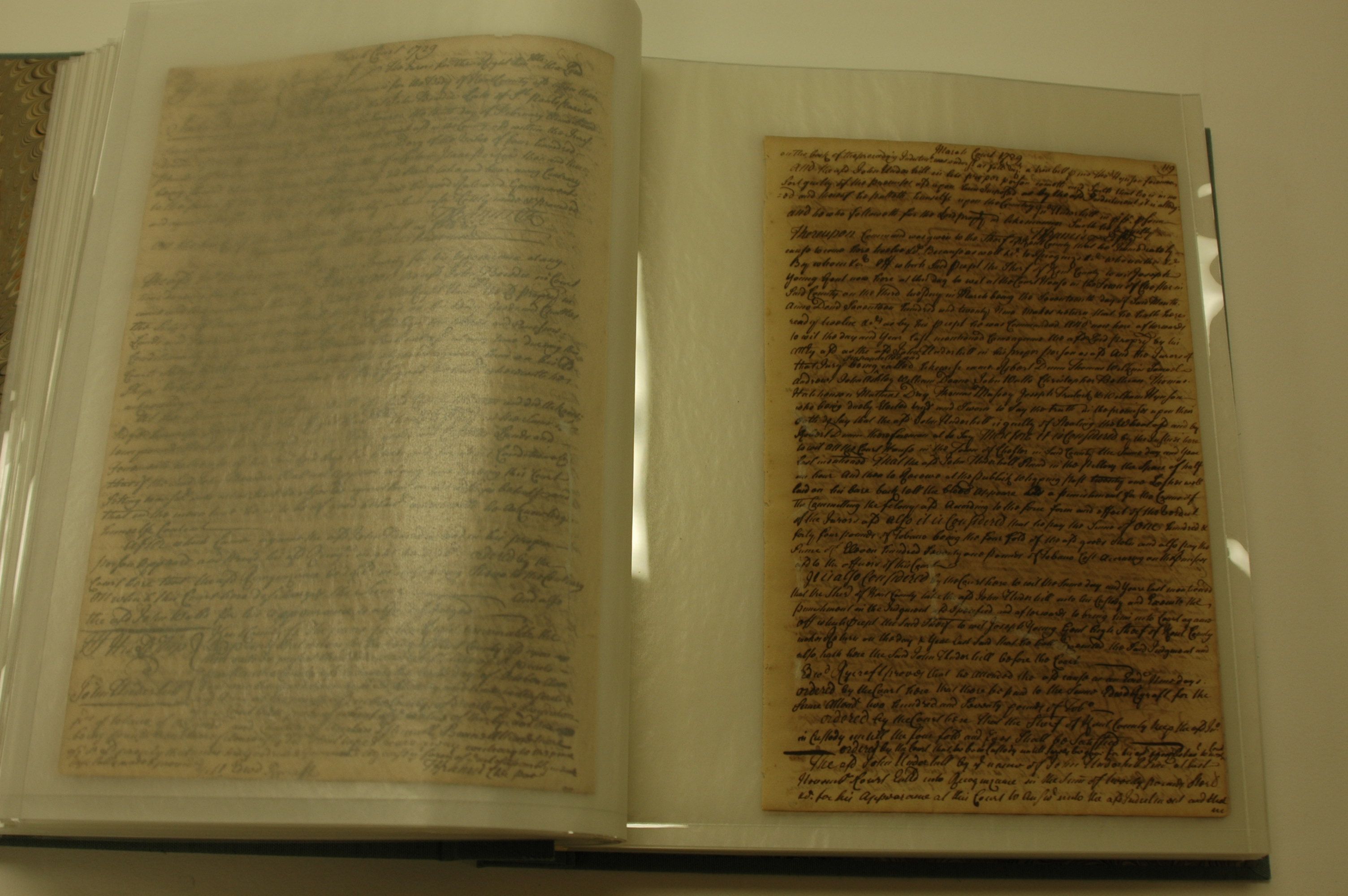

For more about Iron Gall Ink corrosion look here. The binding of the book was in excellent condition, but the paper had been heavily damaged from the use of Iron Gall Ink. Most of the book was classified as in poor condition, due to extensive lacing, pages splitting, and high acidity and the discoloration of the paper Below you can see some of the damage the ink had done to the paper. Due to the ink corrosion, every time a page was turned it split in the exact same place.

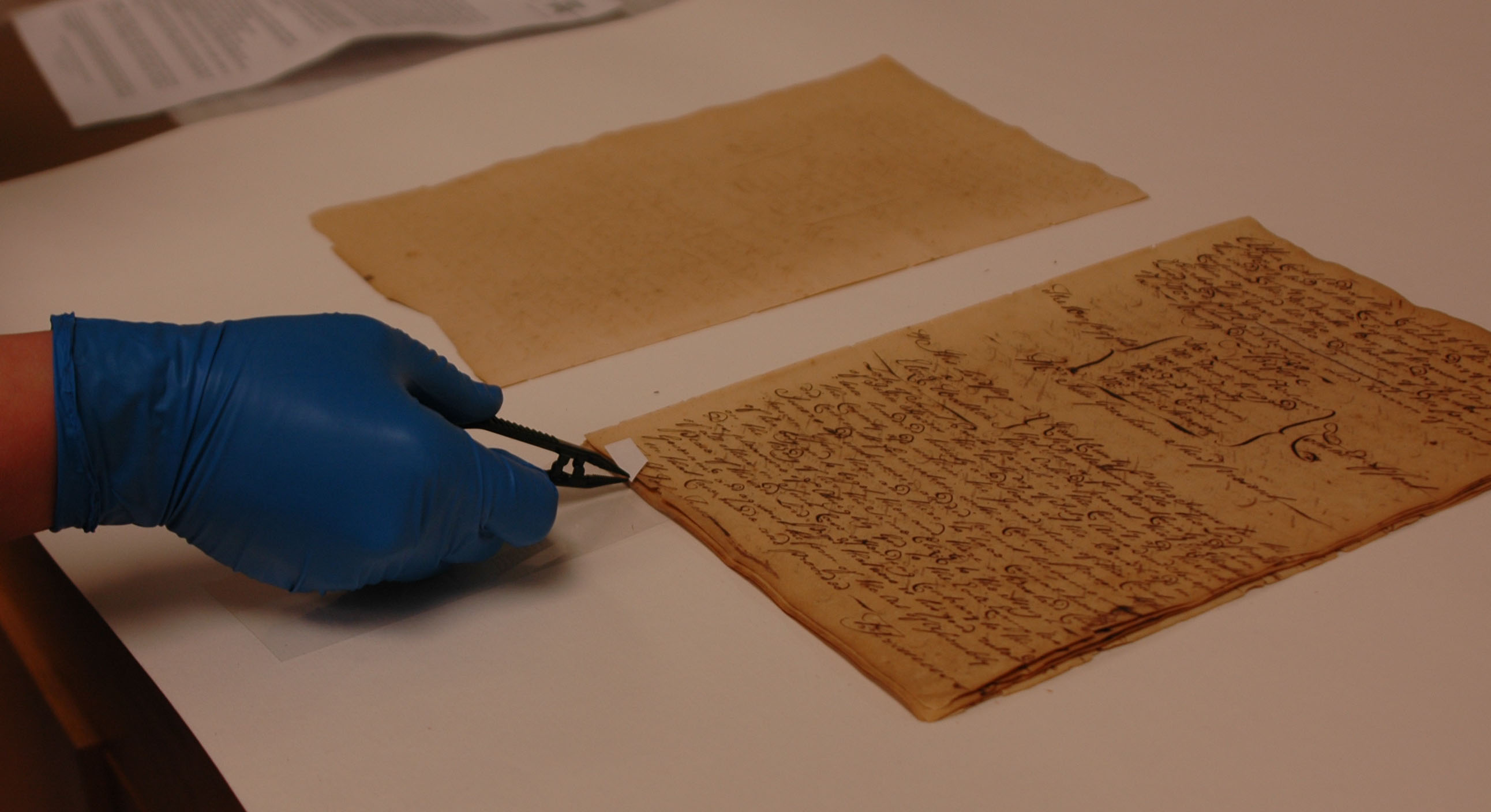

The first step in the repair process was to disbind the book, removing the cover from the text block, then removing one signature at a time. We made sure to test every signature to indicate the presence of extra iron, so that at the end we could see our progress.

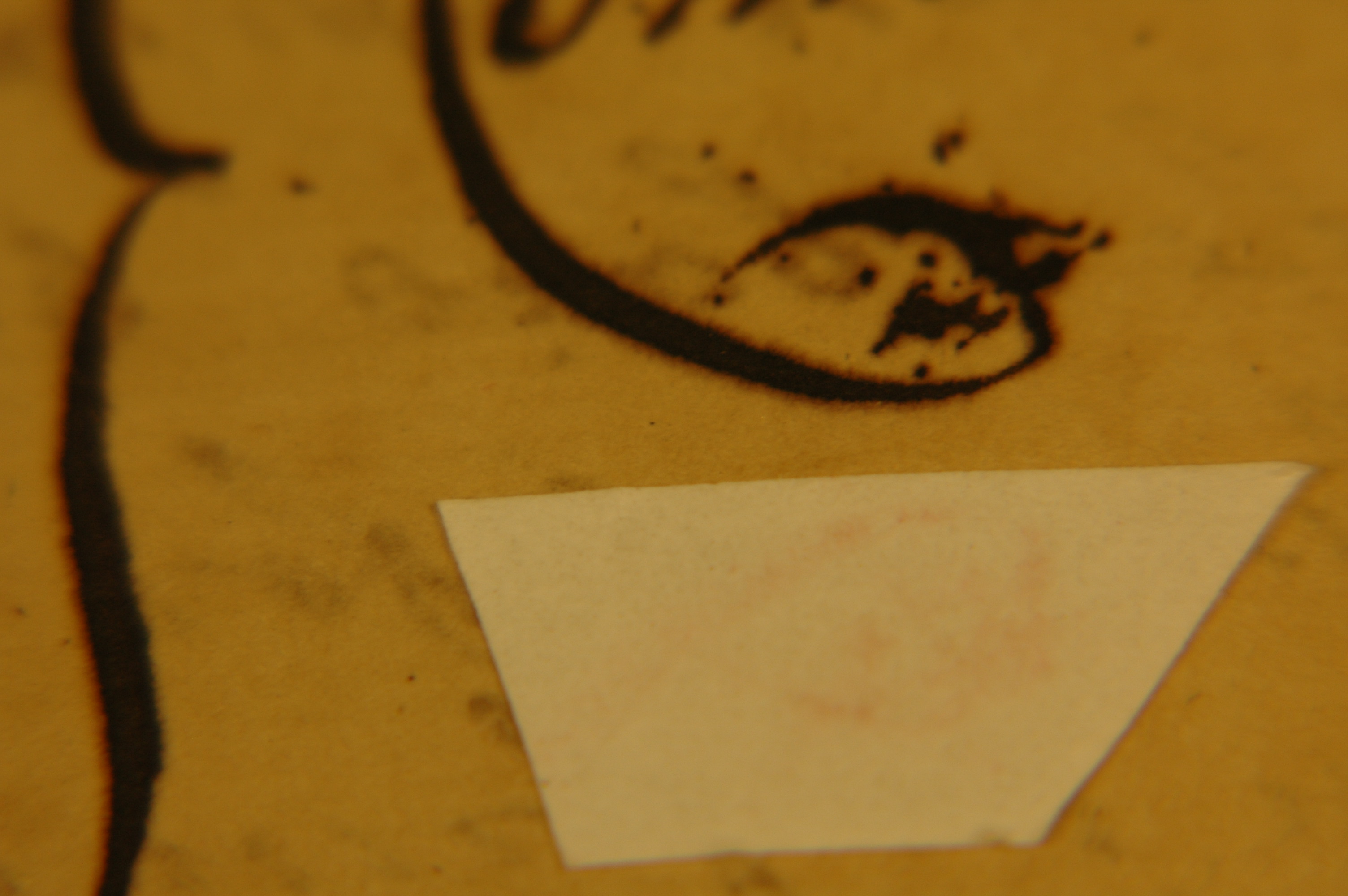

Using special paper, we carefully tested each signature three times. If the paper showed up with a pink outline of the shape of the text, as in the picture below, then we knew the iron was corroding.

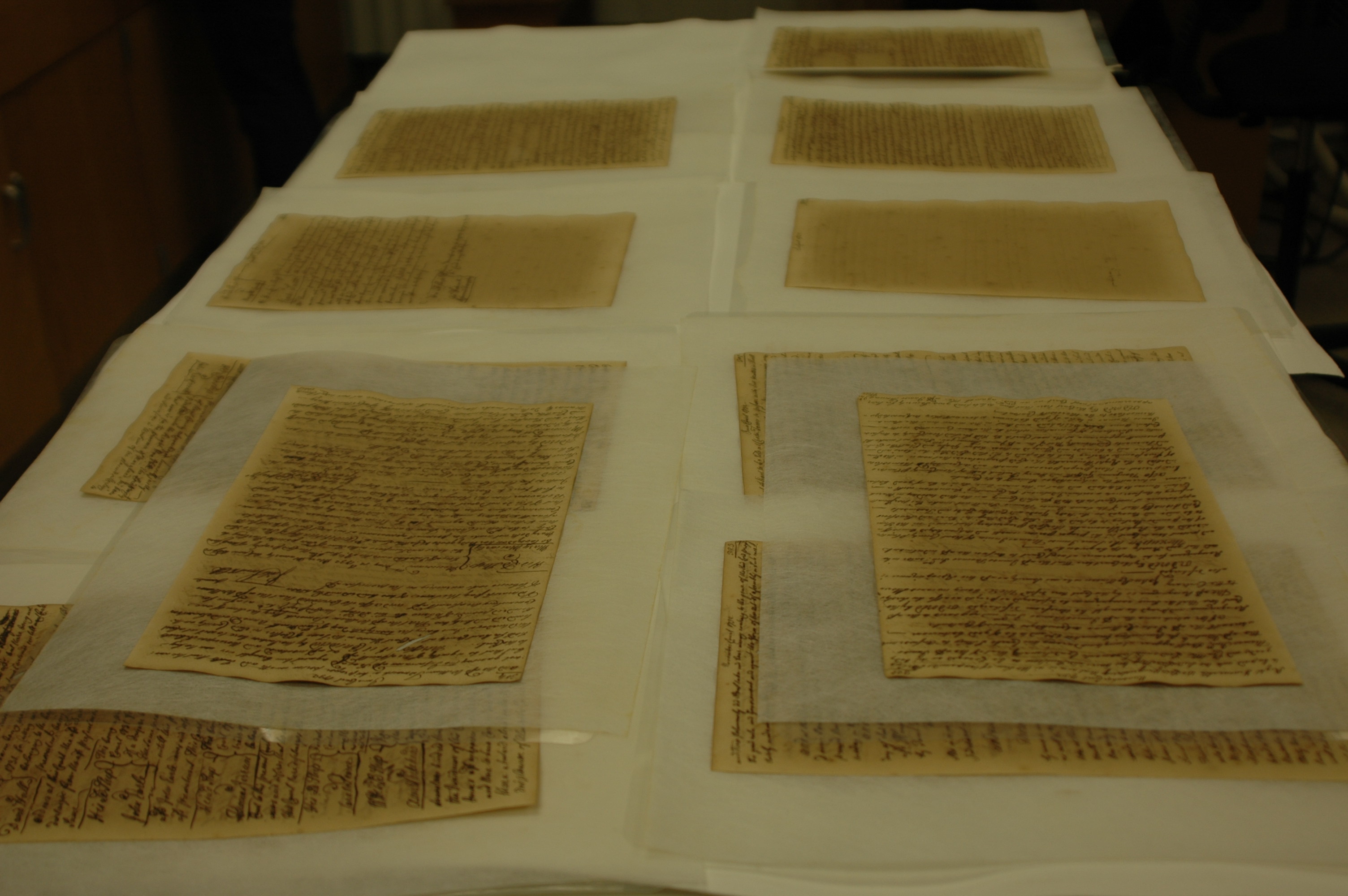

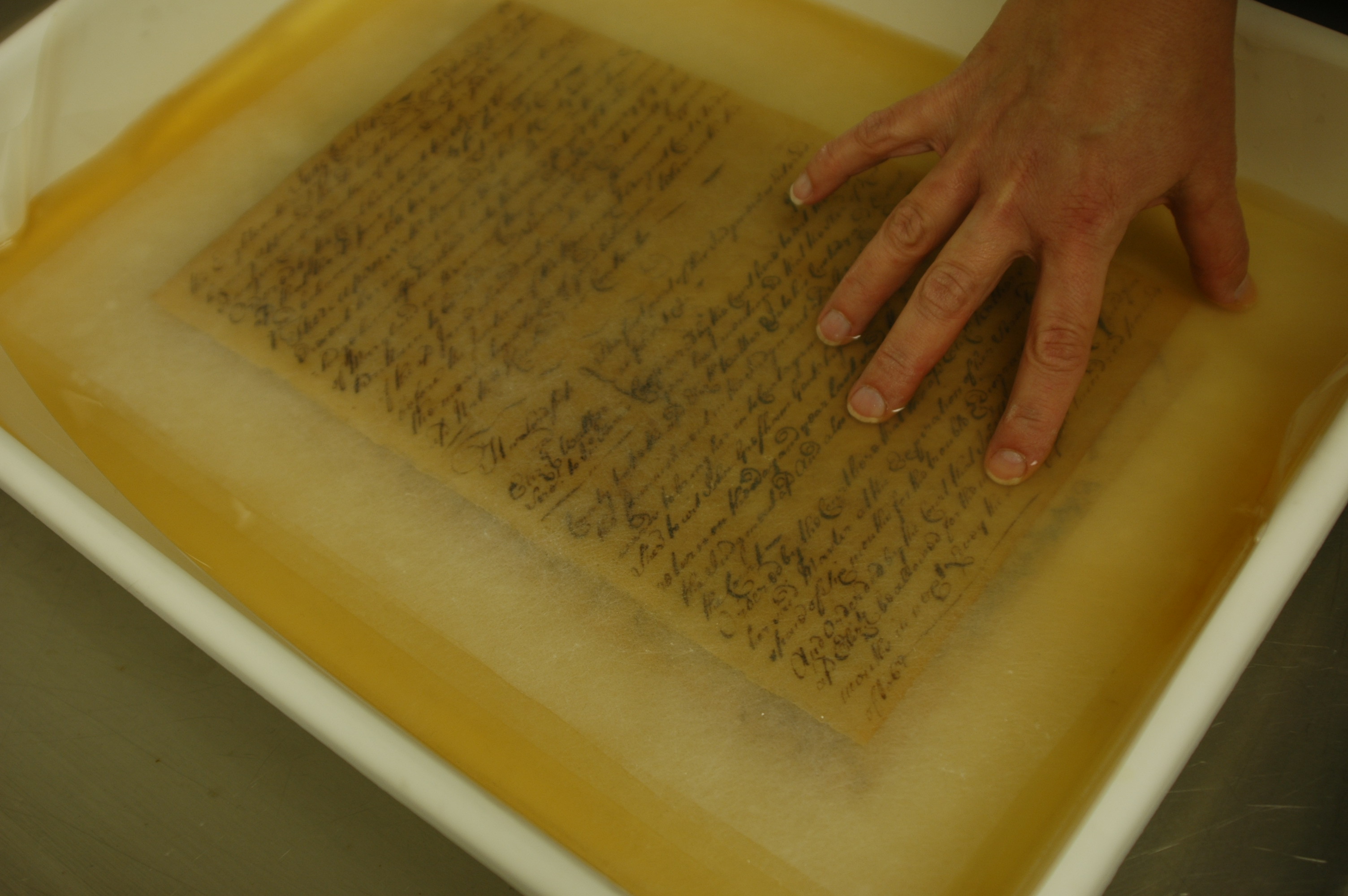

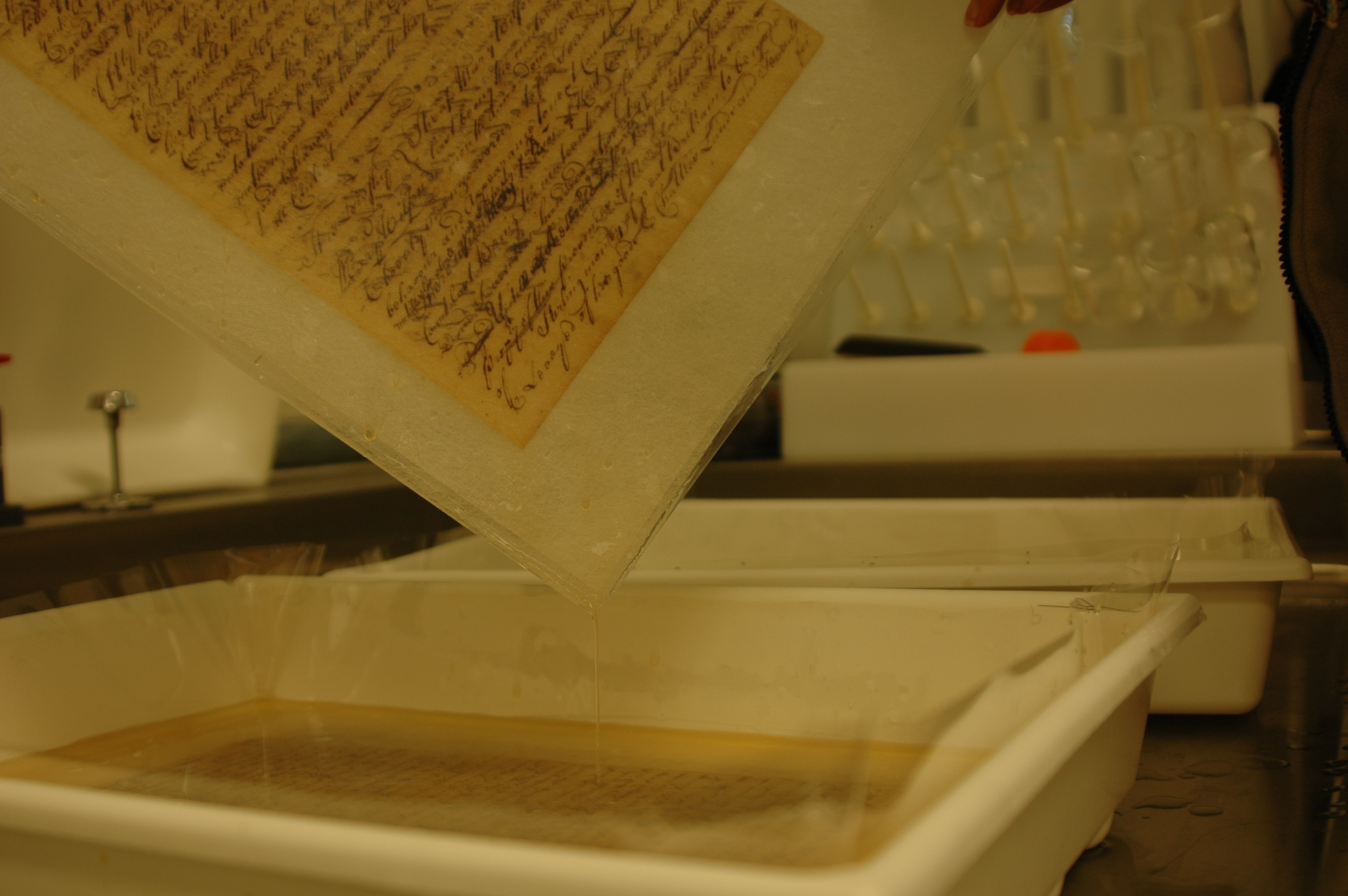

Every page in a signature was separated and layered with polyweave and mylar. The polyweave kept any fragments from being lost and the mylar provided support for the paper when being moved. The next step in the process was to make an acid (phytate) solution to bathe the paper in that would neutralize the extra iron ion that caused the ink and paper to deteriorate. Once the solution was made we sprayed each page with ethanol to allow the acid solution to penetrate the paper better and then carefully placed them into the bath.

After 30 minutes in the phytate solution the pages were carefully removed and put into a calcium hydroxide solution for another 30 minutes. This basic solution was meant to de-acidify the paper, which should help prevent damage from chemical reactions. Each page was bathed twice in this solution.

The finished products were given a location in the stacks and removed to climate controlled storage, where they should last, in good condition, for a very long time. |

Mainpage